A boost for startups: The NC Food Innovation Lab helps entrepreneurs

Published 12:10 am Saturday, May 13, 2023

KANNAPOLIS — For groundbreaking discoveries to occur, commitment and a desire to shake up the status quo need to be at the forefront.

Almost all industries rely on this strategy to thrive, but the N.C. Food Innovation Lab is trying to unearth new methods that can revolutionize the world of food development. It is one of the only innovation labs that has an exclusively plant-based focus.

The lab began roughly seven years ago when Gov. Pat McCrory and the General Assembly realized North Carolina was losing manufacturing within the state.

“We were basically leaving quite a bit of money on the table also from that perspective,” NCFIL Executive Director Bill Aimutis said.

After several committees and groups analyzed what sectors would be the most effective to fund and study, they discovered that the state had many food entrepreneurs focused on the plant-based food space and that they were having a challenging time moving on to full-scale production.

“The one deficiency they found was that these entrepreneurs have no place to go to move from an idea or even a prototype product that maybe they were making in their kitchen, to being able to make it in a pilot plant and eventually in a food manufacturing plant,” Aimutis said.

The general assembly funded the construction of the lab at the N.C. Research Campus. Design work began in July of 2018 and construction started in January 2019 and ended in November that same year. Aimutis says due to COVID and not having all of their equipment right away, the lab didn’t start to make an impression until August 2020.

“We were really going back into hardcore operation and we have not looked back since that date,” Aimutis said.

The lab currently employs 11 people, with more joining the team later on this year. The clientele that partners with the NCFIL are a mixture of entrepreneurs, multinational food companies, universities and engineering firms.

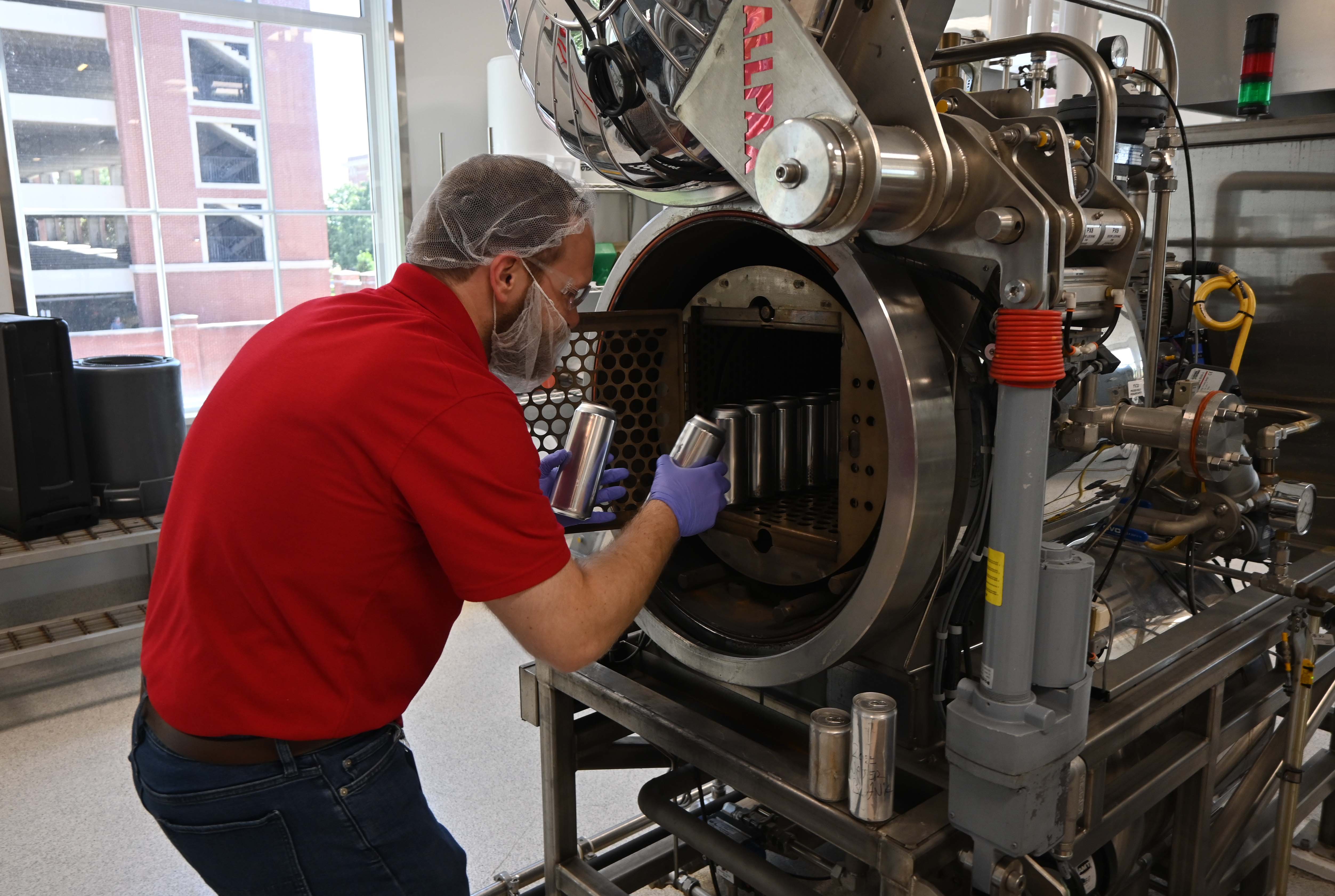

About half of the products the lab deals with are plant-based proteins. They use many “core technologies” for the wide ranging kinds of procedures they undertake. They have sections from a wet processing area to blanch fruits and vegetables to thermal processing for sterilization and water removal. Extraction technology is used to purify or clean up the crude extracts of natural food. Extrusion is heavily used for alternative meats. When making powders, they need to be milled or blended down to a certain particle size so everything is mixed correctly.

Beyond the product development side of things, the NCFIL will guide companies and entrepreneurs in finding funding for and marketing of their products.

“It’s working very closely with the entrepreneurs really from their recipe all the way through to launch,” Aimutis said.

A scale-up packet is provided so business owners can scale up their product with a co-manufacturer if they were going to build a plant around that technology. After realizing some food companies had little knowledge about food manufacturing and scaling up, the NCFIL offered another service where they go out to co-manufacturers and be present for first production runs and first scale-up runs of any new products.

“We also are involved in promoting North Carolina as a potential food valley. We have such capabilities to grow food, process food,” Aimutis said. “We’re really an economic development driver for the state.”

When Maacha Le Blanc’s son was born with a severe intolerance to dairy, she started looking for plant-based milk alternatives that she felt comfortable giving him. She was soon “horrified” to find out that many of those alternatives contained oils, sugars and fillers. Le Blanc then decided there was only one way she could solve this problem.

“I’ll just make my own almond milk!”

Le Blanc experimented at home and soon developed a nutritious, homemade plant-based milk without all of the filler called Milli Mylk. She initially worked with food scientists on a smaller scale, but as her company grew, they needed guidance on manufacturing and altering their recipe for large scale production.

After going through the vetting process with multiple innovation labs and eventually speaking with Aimutis, Le Blanc knew, “He could take us there.”

The main contributions the lab has given Milli Mylk is allowing their milk to still have whole, natural ingredients and its freeze dry technology. Milli Mylk is mainly a direct-to-consumer product, so the freeze drying process goes a long way for sustainable growth.

“By using freeze dry technology, we’re able to remove the water and moisture from the milk, but suspend it at its peak flavor and freshness,” Le Blanc said. Customers are able to get a powdered mixture in the mail, add water, shake or blend, and enjoy.

“I think they have quite a spectrum of different clients with different design approaches, but what I like is they listened and stayed true to our core values,” Le Blanc said.

Milli Mylk is located in Manhattan and has manufacturing in California. The NCFIL was with them on the ground as they met with large-scale manufacturers. As they continue work on new concepts, Le Blanc says they will reach out to the lab this summer to go through their next product line extension. Le Blanc is glad that the lab is able to help them through the pains they’ve grown out of as well as the ones they haven’t experienced yet.

“It takes a village to raise a start up and I feel very grateful that they’re part of this village.”