VA can now make dental crowns on site

Published 12:00 am Thursday, November 20, 2014

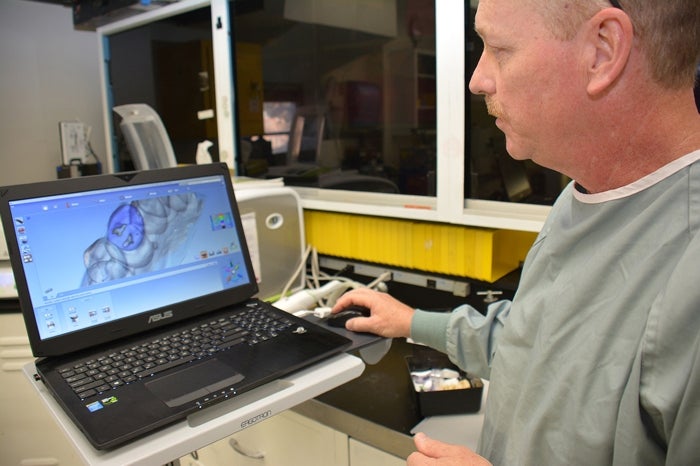

- VA Medical Center Geoff Moon, a dental technician at the Salisbury VAMC, uses the E4D Planscan system to design a crown for a patient. After the design process, the system uses a milling device to create the crown in 10 to 20 minutes.

By Michael Maddox

W.G. (Bill) Hefner VA Medical Center Public Affairs

SALISBURY – Traditionally, the process of getting a dental crown made for a patient at the Salisbury VA Medical Center Dental Clinic could take up to eight weeks, but now thanks to new technology it can be done in as little as a few hours.

The Dental Clinic recently received an E4D Planscan system, which is a Computer Aided Design/Computer Aided Manufacturing (CAD/CAM) dental milling machine that allows the clinic to make its own porcelain crowns for patients, rather than sending them out to be milled at another location.

Being able to make crowns in-house can shorten patients’ wait time considerably, said Geoff Moon, dental technician.

“It’s really good for us because prior to this, we had no capability here on-site to do any type of crowns. We had to ship them out to a VA central dental laboratory and it could take seven to eight weeks to get one back,” he said. “The time savings of being able to make our own is just remarkable.”

Like any process for having a crown prepared, the process starts with making a model of the patient’s teeth from an impression. Dental technicians can then scan the model into the computer so that they can design a crown digitally.

“Once we get it scanned in with 3-D images, we can look at any angle, look at the inside, look at the thickness – about any aspect you could think of,” said Moon. “This machine is on the cutting edge of what’s on the market for digital dentistry as far as milling.”

Once the design is complete, it can be sent to the milling machine that carves the porcelain blank into a crown in 10 to 20 minutes. The entire process can take as few as a couple of hours.

Keith Phillips, staff dentist and director of the Dental Residency Program at Salisbury, said having the ability to create crowns at the medical facility helps patients by requiring fewer trips to the dental clinic.

“It probably takes us about three hours right now to make a crown, so if the patient wants to wait, we can do it that day,” he said. “If we can do it in one visit, which is our target, it can eliminate the patient having to make two trips. It really improves access to care.”

Moon added, doing all of the work in one day also helps other veterans by making follow up appointments less necessary.

“During that seven to eight weeks a patient had to wait for their permanent crown, they can lose their temporary crown. Then we have to have them come in for another appointment and take up chair time to get it fixed,” he said. “Even if everything goes fine with a temporary, it frees up another appointment because they don’t have to come back to have the permanent crown put on – we can do it the same day.”

Phillips said another benefit is that the costs for the materials to make a porcelain crown are less than the cost to mail off a model and have one made at a VA central dental laboratory.

Phillips said getting the equipment was made possible by a Rural Health training and education grant, and there are plans to expand its capabilities in the future to include making bridges. The dental clinic currently still has to order gold crowns and bridges.

“There’s another phase of this coming that will allow us to do bridges,” he said. “Bridges are made from a much harder material than what we use right now. It just requires another oven. The money has been approved for the oven; we just haven’t received it yet.”